Petrochemical Industry and Regulated Testing

The petrochemical industry performs many tests for refined products. Refineries, Inspection and Chemical labs across the world use ASTM, ISO, IP, and other accepted chemical industry standards and protocols. Materials tested include the entire complex range of hydrocarbon based chemicals derived from petroleum. This also applies to primary petrochemicals including olefins, aromatics, and synthesis gas. Petrochemical testing can extend to trace and ultra-trace level analysis. Chemical testing expertise includes purity & component, trace composition, trace contamination, quality control, troubleshooting, and other chemical analysis expertise. ASTM chemical testing methods are utilized by laboratories for chemical analysis of petrochemicals, compounds, materials, petroleum, fuels, consumer products, and other chemical substances.

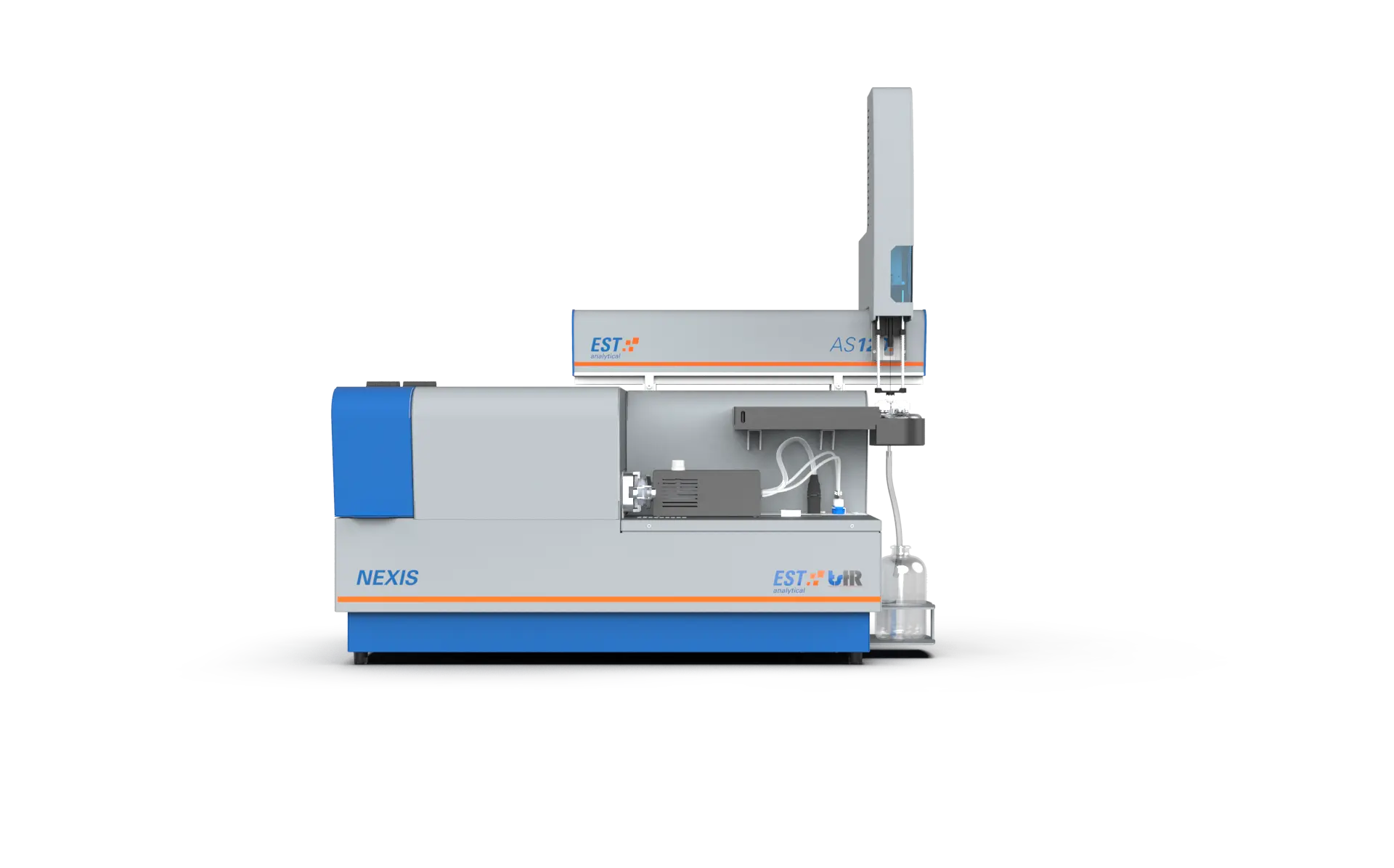

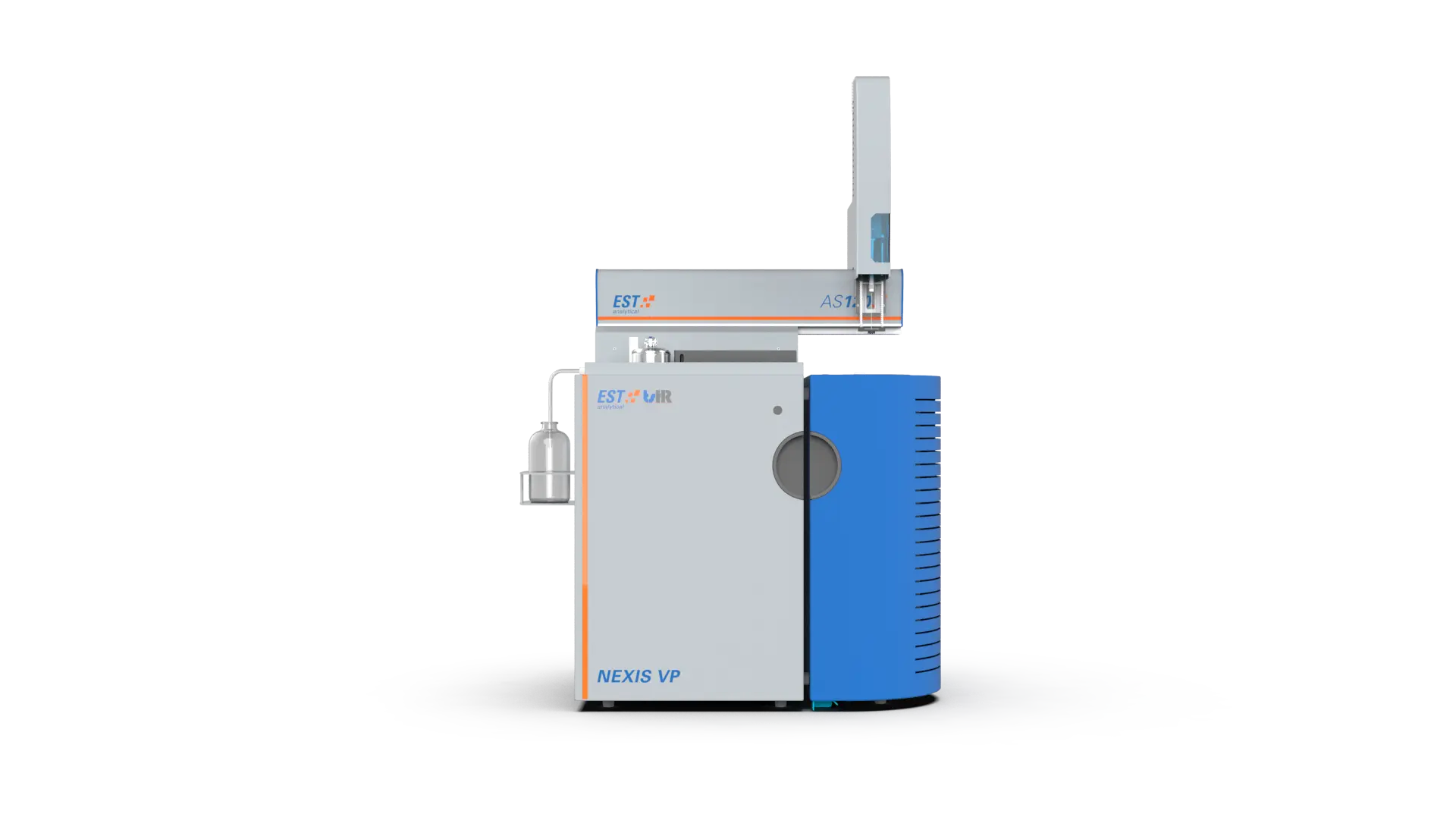

ASTM chemical test methods are industry accepted standards for quality control and reliability. Testing measures require trace analysis to ppm, ppb, and ppt levels. Petrochemicals and chemicals are tested for quality control, purity, contamination, research and development, troubleshooting, environmental evaluation, regulatory compliance, and more. No matter what your combustion applications require EST Analytical has a solution for you. Innovative solutions for liquids, solids, and LPG’s are provided in either our horizontal system the Nexis or vertical system the 7000. EST provides full service, parts and technical support to keep your labs running seamlessly.