Sample Preparation

Sample preparation is one of the most important steps in analytical chemistry. Preparation can vary from extractions to dilutions to standard preparation. Attention to detail and accuracy are essential. Automation can remove costly errors and improve precision and accuracy while protecting the analyst from repetitive motion injuries and toxic substances.

Quantitative analysis requires not only sample prep but also standard prep. When preparing a calibration curve, the analyst has to follow a recipe in order to ensure standard accuracy. Any error in the standard preparation and the calibration curve will need to be re-prepped and re-run. Thus, valuable time and resources are wasted.

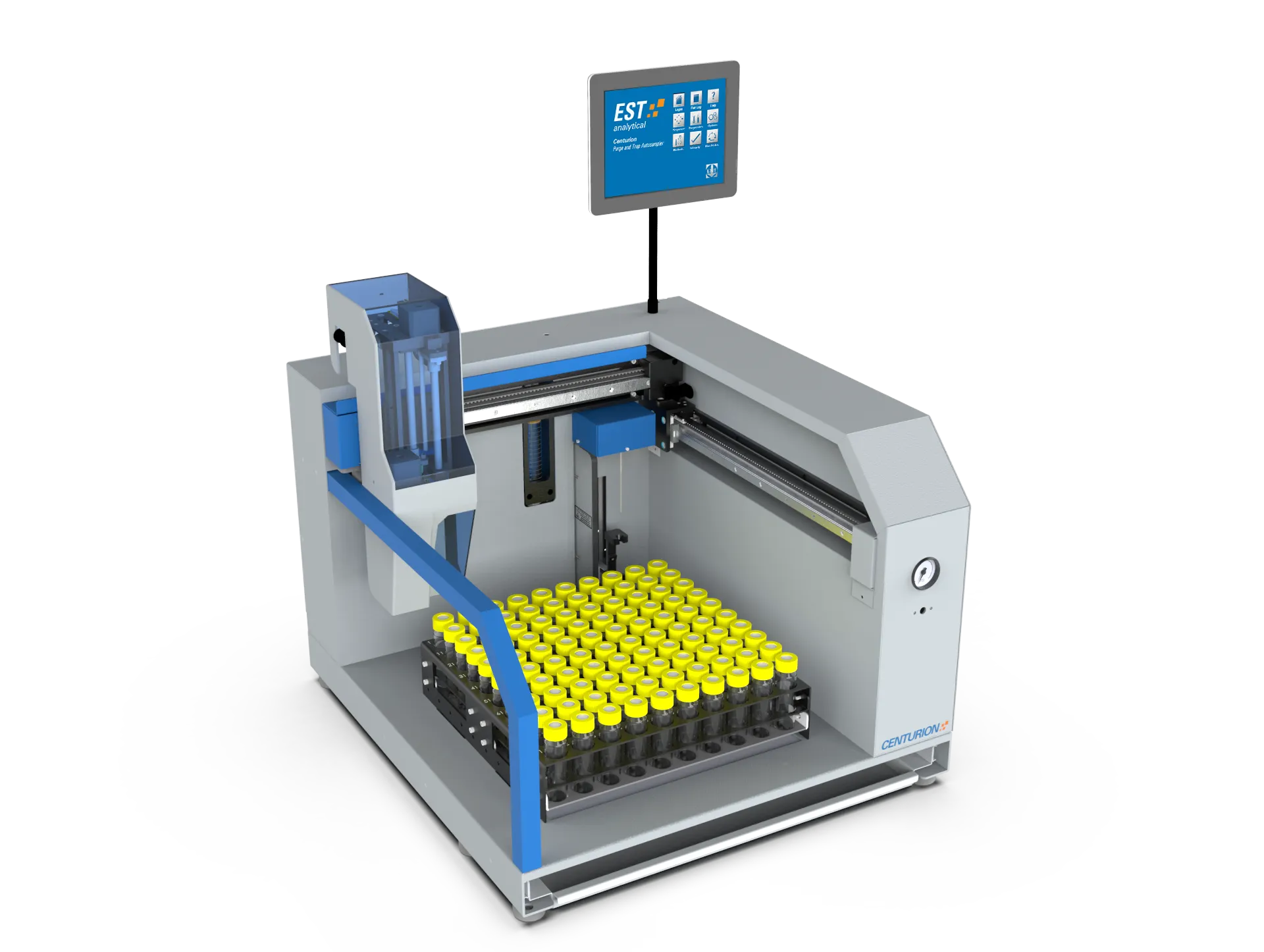

The EST FLEX 2 Robotic Sampling Platform is capable of performing standard preparation and liquid/liquid extraction for small volumes. The FLEX 2 can be placed on your benchtop for sample prep or installed on top of a GC system for both sample prep and sample analysis automation.

Whitepapers

The American Society for Testing and Materials (ASTM) Method D8028 is a method to determine dissolved gases in water. The method describes calibration and sampling techniques. One of the recommendations is to ensure the sample is sealed in order to safeguard the integrity of the sample. This recommendation is taken from United States Environmental Protection Agency (USEPA) Method 5030C used for the sampling of volatile organic compounds in water. Many environmental labs currently open their dissolved gas samples in order to place them in a headspace vial for sampling and analysis. This application will compare the efficacy of ensuring the sample is sealed versus opening the sample and pouring it into the sample vial for analysis.

The RSK-175 standard operating procedure was developed in order to determine the amount of dissolved gas in water. However, since the RSK-175 standard is a standard operating procedure and not a formal method, there have been many interpretations and modifications of RSK-175 in order to determine the amount of gas dissolved in the water. This paper will consider three different approaches for dissolved gas calibration and analysis and the respective pros and cons.

Hydraulic fracturing or “fracking” has become a commonplace technique for the recovery of natural gas from deep beneath the earth’s surface. As a consequence, there has been a rise in the concern of gases escaping during the “fracking” process and contaminating nearby water sources. Testing for dissolved gases has, until recently, been done following the RSK-175 standard operating procedure. However, as RSK-175 is not an accredited method, different interpretations of the method have been employed. In order to address this issue, a formal method has been published by the American Society for Testing and Materials (ASTM) Committee D-19. This application will test for dissolved gases using a Certified Reference Material (CRM) for Methane, Ethane, Ethylene and Propane using the procedures outlined in the D-8028 ASTM method.

In order to test for possible dissolved gas contamination, most laboratories refer to a standard operating procedure entitled “RSK-175”. This procedure calls for static headspace sampling of the water samples and calculating the amount of dissolved gas using Henry’s Constant. However, as RSK-175 is standard operating procedure and not a formal method, interpretations can vary. In order to address this issue, a formal method is currently being written by American Society for Testing and Materials (ASTM) Committee D-19. This application will test for dissolved gases using the procedures established in the ASTM method.

Due to the expansion of natural gas drilling through horizontal fracturing, there has been increased interest in the RSK-175 Standard Operating Procedure (SOP) for the determination of dissolved gases in water. This paper will discuss calibration by using static headspace sampling of vials spiked with different volumes of mixed gases. Furthermore, the precision and accuracy of the calibration will be established by headspace screening of mixed gas standards and also by examining known concentrations of dissolved gases and back calculating experimental results using the Henry’s Constant and the saturated gas calculation.

Tapping the natural gas reservoirs throughout the United States has long been a viable solution for energy independence; however until recently getting to these gas reservoirs was very difficult. Now, through the development of horizontal drilling in conjunction with hydraulic fracturing or “fracking”, these reservoirs have become much easier to tap for natural gas. However, there are some environmental concerns with the fracking process that have come to light as fracking has gained popularity. One major concern is the potential for natural gas to migrate into drinking water sources. In order to test for dissolved gases, the RSK-175 Standard Operating Procedure (SOP) was developed. Since RSK-175 is an SOP and not an EPA or ASTM method; laboratories have employed different approaches in order to calibrate for the dissolved gases. This study will evaluate a standard calibration using serial dilutions of saturated gas samples. The LGX50 autosampler will do the rest of the work by creating headspace in the sample vial while maintaining sample integrity and transferring the headspace to a GC/FID for analysis. This automation provides the capability to treat calibration samples in the same manner as field samples thus reporting field sample results requires no back calculation using the Henry’s Constant.

Our Impact

EST Analytical has been helping labs achieve their analytical goals for over 30 years. Our vision is to engineer reliable laboratory instruments that enable partners to make the world a better place.

To help labs excel we offer Application Notes across our entire product line. They are a resource that explains the technology, performance, and abilities of our products as used against certain methodologies and or applications.

Whether your needs center around a USEPA method, an ASTM Standard, or a sample matrix-based outcome EST has you covered. If you don’t see the technical direction you need, simply contact us. We also offer sample analysis in our onsite Applications Lab.