EPA Drinking Water by Purge and Trap

Method 524.2 encompasses 84 volatile organic compounds (VOCs) including trihalomethanes which are common byproducts of disinfection. Sample size can be as high as 25mL to as low as 5mL as long as the analytical system can reach the required detection limits. Therefore Samples need to be purged at 40mL/min with Helium for 11 minutes and desorbed for about 4 minutes. Since EPA drinking water by purge and trap and 524.2 is a prescriptive method, these purge and trap parameters may not be altered. Accordingly there are some who experience excess moisture due to the longer desorb time in this method. In addition moisture can negatively affect resulting chromatography in EPA drinking water by purge and trap. If your compliance officer is mandating a 4 minute desorb, ask about EST’s patented Desorb Flow Control (DFC) available on the Evolution 2.

Over the years, there have been many improvements to purge and trap and Gas Chromatography/ Mass Spectrometry (GC/MS) systems. They have better sensitivity and are much more efficient in analyte separation and analysis. For this reason, EPA drinking water by purge and trap and USEPA Method 524.2 was updated with USEPA Method 524.3 and 523.4 with the Method 523.4 allowing for laboratories to use Nitrogen as a purge gas. There are several updates to the drinking water method and right now laboratories can choose which method that they would like to use.

Whitepapers

In June 2009, the United States Environmental Protection Agency (USEPA) promulgated a new drinking water method, 524.3. Due to advances in analytical instrumentation, Method 524.3 allows laboratories to modify purge and trap and GCMS conditions. Currently the USEPA is investigating the option of using Nitrogen as the purge gas in a new drinking water method, 524.4.

Desorb flow control was developed in order to help manage the moisture associated with the four minute desorb time required for USEPA method 524.2. An added benefit to this process is the reduction in helium consumption when using this technique. This application will explain the patented process of Desorb Flow Control (DFC) (United States Patent Office numbers: 8062905, 7951609, 7803635) for helium conservation and moisture control.

The United States Environmental Protection Agency released Method 524.3 with some changes that incorporated some of the advances in purge and trap technology. One of those modifications allowed for the purge flow and time to be revised in order to make the purge and trap cycle times shorter and allow laboratories to be able to test more samples. This application will examine two different purge flows and times and compare the corresponding results.

Algal contamination in drinking water is becoming a common problem. The primary compounds that result from this contamination are 2-Methylisobomeol (2-MIB) and Geosmin. These compounds cause a musty odor in water and since the odor of these compounds have a very low threshold for detection, small amounts of contamination can cause drinking water to taste and smell unpleasant. This application note will investigate the detection of 2-MIB and Geosmin down to a 1ppt level.

The compounds 2-Methylisoborneol (2-MIB) and Geosmin are the primary source of the foul odor found in drinking water. Algal contamination is the principal cause of the formation of these compounds. Geosmin and 2-MIB have such a low odor threshold that even the slightest amount can produce an unpleasant odor and taste in drinking water. Thus, developing a reliable sampling and analysis platform for very low level detection is important. Standard Method 6040D describes a procedure for the detection of 2-MIB and Geosmin using Solid Phase Micro Extraction (SPME) coupled with a Gas Chromatograph (GC) and Mass Spectrometer (MS). Selective Ion Monitoring (SIM) is used for compound detection down to part per trillion (ppt) levels. This examination will optimize the sampling and detection of 2-MIB and Geosmin.

Geosmin and 2-Methylisoborneol have an unpleasant odor and a very low odor threshold. The aroma of these compounds can be detected by smell at levels below ten parts per trillion. Thus, developing a reliable sampling and analysis platform for low-level detection is important. The use of Solid Phase Micro Extraction for the sampling of Geosmin and 2-Methylisoborneol is described in Standard Method 6040D. This application will examine the difference between two SPME sampling devices for the extraction of these compounds.

During volatile analysis, samples are purged with an inert gas in order for the Volatile Organic Compounds (VOCs) to be swept out of the sample matrix and onto an analytical trap. For years, the established purge flow rate and time has been 40ml/min for 11 minutes. USEPA Method 524.3 changed this. This new method allows for different purge flows and times and outlines recommended and allowable ranges. This application will examine how different purge flows and times affect compound performance for Method 524.3.

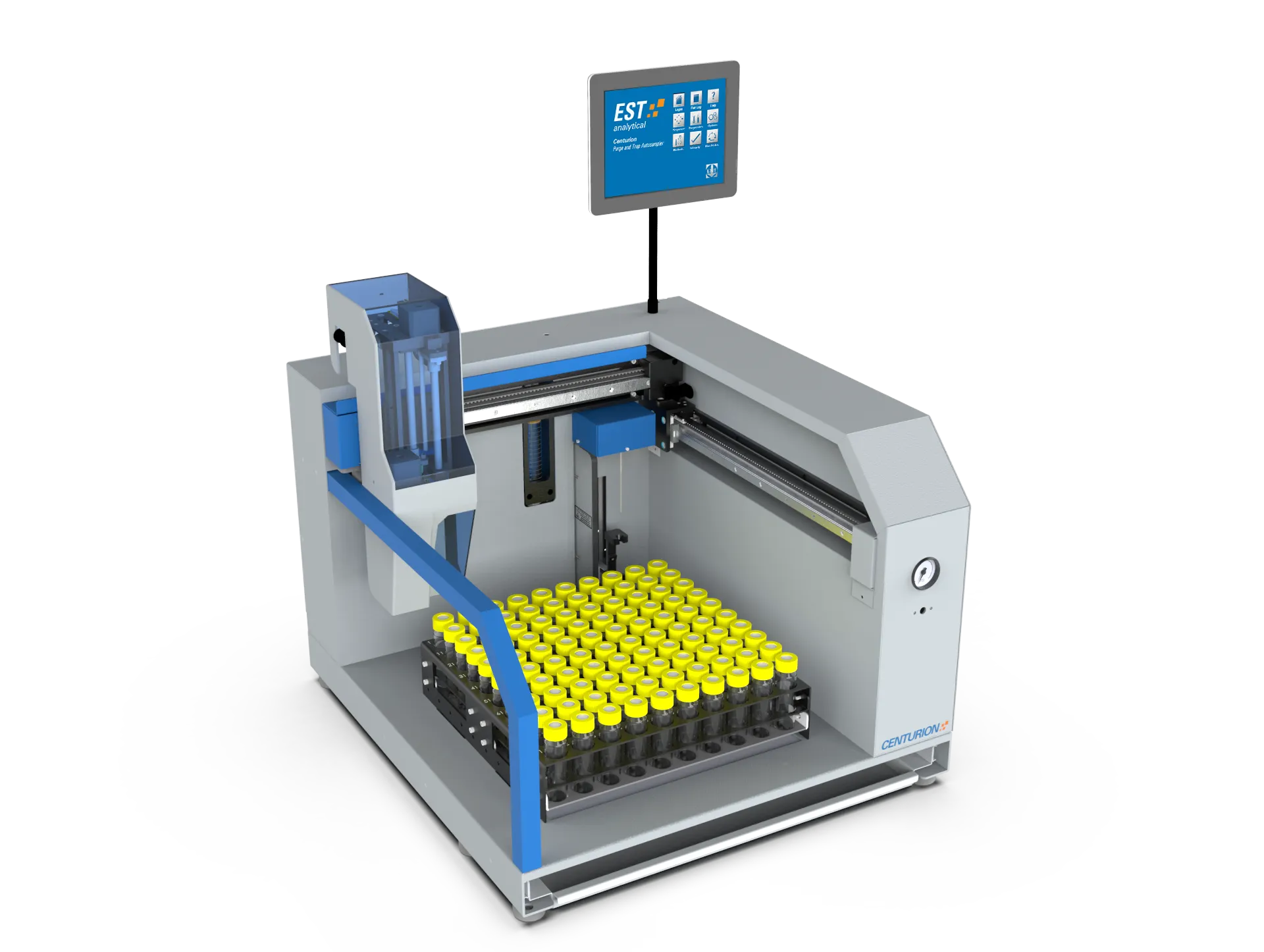

The United States Environmental Protection Agency (USEPA) created Method 524.2 for the examination of purgeable organic compounds in surface, ground and drinking water. There are a wide range of compounds listed in the method including four trihalomethanes which form when water is chlorinated. This application will examine USEPA Method 524.2 employing the new Evolution 2 purge and trap concentrator.